100L Nano Home Beer Brewing Equipment

- YUXIN

- China

- 30-40 days

- 500 sets per year

100L Nano Home Beer Brewing Equipment

Stainless steel or red copper material;

Can make it mirror surface;

Can be movable with wheels;

Electric heated by electric heating coil inside;

Supply drawings, layout, pipeline diagram, loading diagram etc.;

Engineer will go there for installation/debugging and trainning .

100L Nano Home Beer Brewing Equipment

Items | Equipment |

Milling system | Malt miller |

Brewhouse system | Mash/Lauter tun |

Kettle/whirlpool tun | |

Hot liquor tank(optional) | |

Plate heat exchanger | |

Wort pump | |

Wort oxygenator | |

Fermentation system | Fermenter |

Bright beer tank | |

Cooling system | Glycol water tank |

Chiller | |

Glycol water pump | |

CIP system | Alkali tank |

Sterilization tank | |

Water pump | |

Control system | Digital display control system |

1. Brewhouse System

Mash tun, Lauter tun, Kettle, Whirlpool tun in various combination;

Hot water tank and cold water tank for optional in special combinations;

Completely stainless steel integrated work platform;

Sanitary and efficiency wort pump;

All piping and fittings.

2. Fermentation System

Standard stainless steel conical cylindrical fermentation tanks;

Single size or double size as brewhouse is common used in microbreweries;

Tanks quantity is exactly calculated by fermentation cycle for various beers;

All manhole, valves, pressure gauges, fittings etc are included.

3. Cooling System

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing;

Efficiency chillers or refrigerators supply cooling energy;

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger;

All pipes, fitting, insulation materials are included.

4. CIP System

5. Control System

Details:

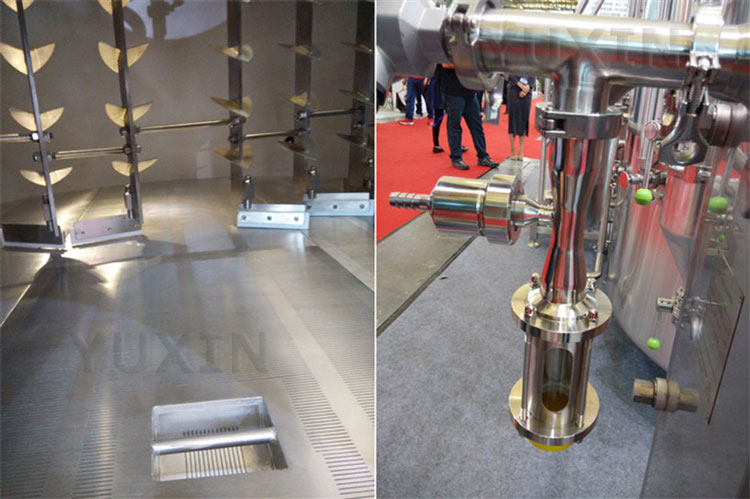

Details for Polished and Fine welding on the Beer Brewing Equipment /100% TIG WELDING/Automatic Grain System/Sanitary food grade