10BBL Customized Brewing Equipment

- YUXIN

- China

- 30-40 days

- 300 sets per year

YUXIN Customized Brewing Equipment

Customized as your idea

Supply drawings, layout, pipeline diagram, loading diagram etc.

Engineer will go there for installation/debugging and training.

Electric/steam/direct fire heated

2vessels, 3 vessels, 4vessels etc.

with agitator

automatic controlled by pneumatic valve

10BBL Customized Brewing Equipment

Micro Beer Brewery Equipment is widely applied to brewing various types of beers. It is popular in pub, hotel, restaurant such commercial places. Invest little, easy to get profit, you can get it in the same year , so it is a good choice for you.

We elaborately customize innovative-technology craft beer brewing equipment in personalization for every brewer/winemaker. And focus on stainless steel vessels and pay attention to high-end manufacturing and sincere service.

System | Specification |

Milling System

| Malt mill equipped with motor, pulley, belt, etc. |

Brewhouse System

| Mash /lauter tun, kettle/whirlpool tank |

hot liquid tank Steam heating, electric heating, direct fire heating | |

SUS304, thickness: 2.0-3.0mm | |

Rock wool, thickness: 80mm | |

Fermentation system

| Several fermentation tanks, BBT |

SUS304, thickness: 2.0-3.0mm | |

Polyurethane, thickness: 80mm | |

Cooling System

| Glycol water tank, chiller |

SUS304, thickness: 2.0-3.0mm | |

Polyurethane, thickness: 80mm | |

CIP system

| Disinfection tank,alkali tank,CIP trolley |

Clean all tanks before brewing beer or finish brewing beer. Use acid to clean firstly, secondly is alkaline,then is H2O2, finally is water. Then begin to brew beer | |

Control System | PID control box or PLC with touch screen |

Main Parts:

1. Milling System(stainless steel or carbon steel)

2. Brewhouse System

3. Fermentation System

4. Cooling System

5. CIP System

6. Control

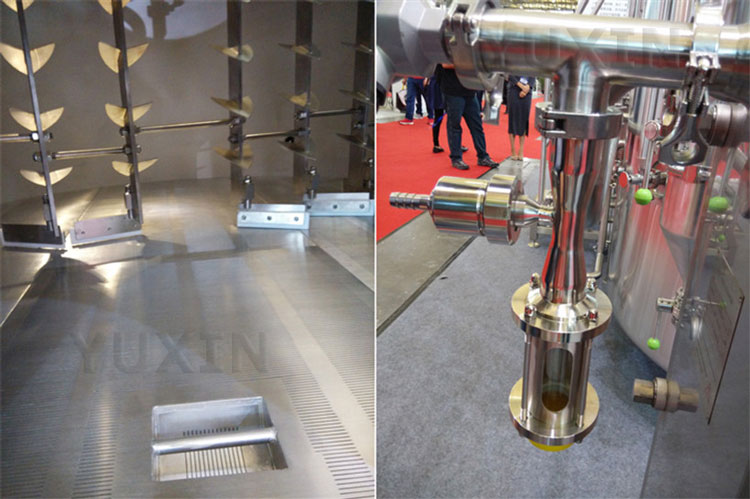

Details Images: