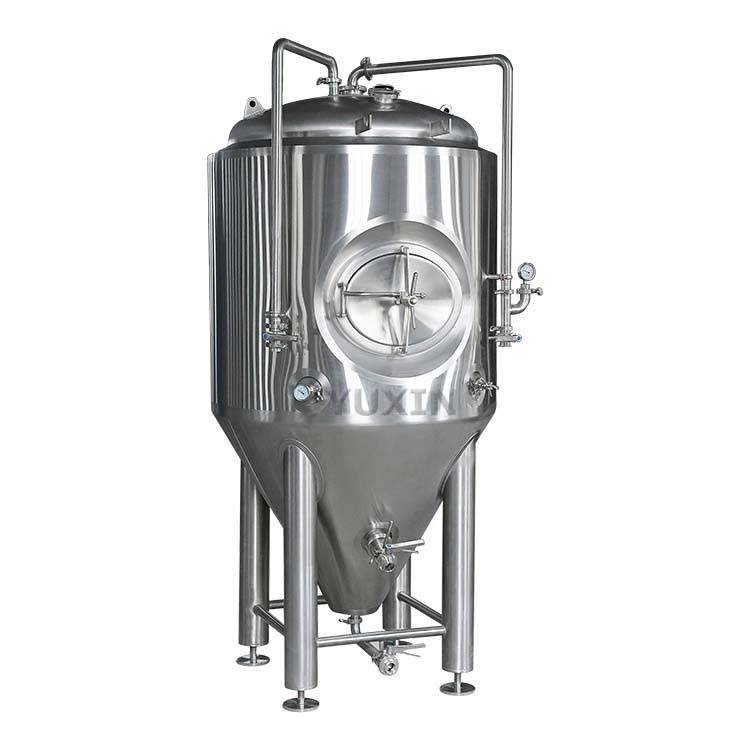

30BBL Beer Unitank

- YUXIN

- China

- 25-30days

- 100sets/month

30bbl beer unitank

dimple cooling jacket

double walls and insulation

carbonation port and stone

racking arm

dry hopping port

safety valve

sample valve

pressure valve and gauge

30BBL Beer Unitank

With 25% head space;

Inner(SUS 304) thickness: 3mm;

Outer(SUS 304) thickness: 2mm;

Insulation: Polyurethane, thickness=80mm;

Single tank single control;

CIP arm and 360° spray ball;

Pressure relief valve on CIP arm;

Pressure gauge on CIP arm;

Safety valve on the top;

Stainless steel dimple cooling jacket on cone and side;

Coolant inlet and outlet;

Sanitary sample valve;

Dish top, 60 degree cone bottom;

Stainless steel side/top manway;

Racking arm for beer outlet;

Wort inlet and yeast outlet;

Carbonation stone and port assembly;

Interior and exterior finish polished to a sanitary finish;

Interior finish pickled and passivated;

Sanitary tri-clamp connections;

Stainless steel legs with stainless leveling footpads.

Accessories:

No. | Name | Quantity | Technical Parameters |

01 | Solenoid valve | Assort | Working voltage: DC24V. Inlet and outlet pipe diameter: DN20. |

02 | Pressure relief valve | Assort | Material: stainless steel 304 |

03 | Safety valve | Assort | Material: stainless steel 304 |

04 | Pressure gauge | Assort | Working range: 0~0.6MPa Working accuracy: 0.01MPa |

05 | Temperature probe | Assort | Accuracy: 0.1℃. |

06 | Temperature transmitter shell | Assort | Aluminum alloy shell, resistance to electromagnetic interference. |

07 | Sampling valve | Assort | No dead corner |

08 | Refrigerant piping | Assort | Material: PPR |

09 | Insulation pipeline | Assort | Polyurethane |

10 | Pipeline & Valves | Assort | Health food grade pipeline; Butterfly valve, no dead corner, sterilization more comprehensive. |

Pressure valve and gauge:

Sample valve, side manway, racking arm etc.

Carbonation port and stone:

Tanks interior:

Packaging:

Air bubble film, stretching membrane, steel shelf, free-fumigation wooden box, to make everything safe in containers.

Service:

-Drawings: Engineer will make drawings for your confirmation before production;

-Layout: Engineer will design the layout of how to place the brewery/fermenters;

-Customized: Equipment&Tanks all can be customized as your requirement and your actual space.

-Report during production: We'll take photos or videos to report you each step here.

-Installation: Our engineer will go to your site to install/debug the brewery, and train you or your brewmasters how to operate the equipment. Engineer will also supply some beer recipes if you are new in brewing.

-After-sale service: We'll keep supplying free service after sales, and will answer your confusion timely. We'd like to send you accessories by express or send our engineer to go there for service on site if any problem.

Our workshop:

Customers visiting:

Cases:

Our Exhibition:

Certificates: