500L Micro Beer Brewery Equipment

- YUXIN

- China

- 30-40 days

- 300 Sets per Year

Micro Beer Brewery Equipment is widely applied to brewing various types of beers. It is popular in pub, hotel, restaurant such commercial places. Invest little, easy to get profit, you can get it in the same year , so it is a good choice for you.

A set of brewery equipment is generally equipped with malt mill, mash/lauter tun, kettle/whirlpool tank, fermentation tank, bright beer tank, cooling system, CIP cleaning system and controlling system. Micro brewery equipment use stainless steel 304.

We elaborately customize innovative-technology craft beer brewing equipment in personalization for every brewer/winemaker. And focus on stainless steel vessels and pay attention to high-end manufacturing and sincere service.

500L Micro Beer Brewery Equipment

Production Description:

System | Specification |

Milling System

| Malt mill equipped with motor, pulley, belt, etc. |

Brewhouse System

| Mash /lauter tun, kettle/whirlpool tank |

hot liquid tank Steam heating, electric heating, direct fire heating | |

SUS304, thickness: 2.0-3.0mm | |

Rock wool, thickness: 80mm | |

Fermentation system

| Several fermentation tanks, BBT |

SUS304, thickness: 2.0-3.0mm | |

Polyurethane, thickness: 80mm | |

Cooling System

| Glycol water tank, chiller |

SUS304, thickness: 2.0-3.0mm | |

Polyurethane, thickness: 80mm | |

CIP system

| Disinfection tank,alkali tank,CIP trolley |

Clean all tanks before brewing beer or finish brewing beer. Use acid to clean firstly, secondly is alkaline,then is H2O2, finally is water. Then begin to brew beer | |

Control System | PID control box or PLC with touch screen |

1. Milling System

Capacity: 80~1000kg/h;

Description: Motor, double roller, distance adjustable;

Material: stainelss steel 304 or carbon steel;

Optional: Flexible Auger.

2. Brewhouse System

- 2~4 vessles or combined system.

- Material: Stainelsss steel 304 or red copper

- Effective volume: 100L~ 5000L,1BBL~ 50BBL.

- Heating methord: Steam heated, electrical heated or direct fire

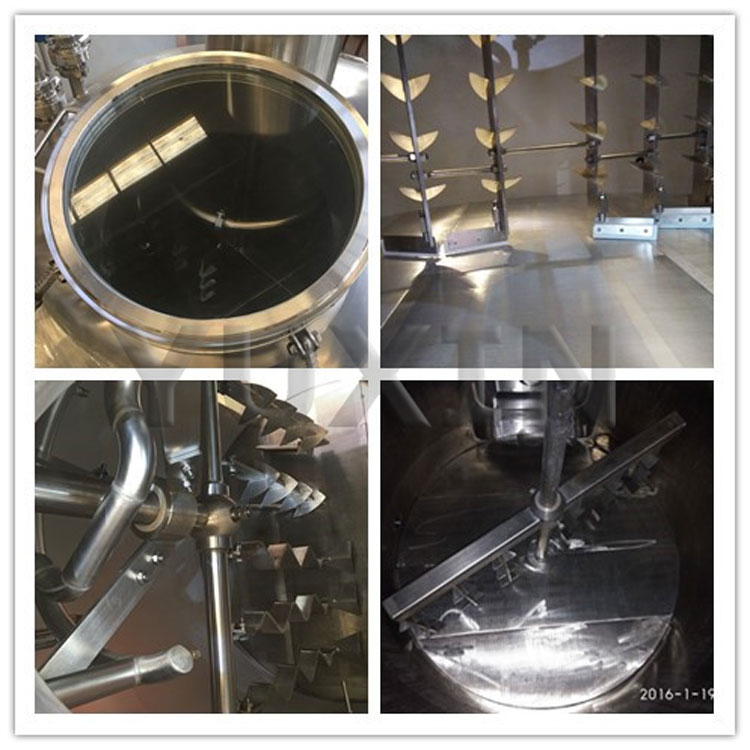

- Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

- Lauter tun with rake system, milled false bottom, sparging spray ring, motor, insulated 80mm.

- Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

- Whirlpool with Tangential whirlpool inlet. insulated 80mm. Stainelsss steel 304.

- Insulated HLT with the pipelines and pumps

- Plate heat exchanger., working platform.

- All the necessary pipelines and pumps.

3. Fermentation System

- Effective volume: 100L-30000L, 1bbl-100bbl

- Material: Stainelsss steel 304

- Interior shell thickness 3mm, Exterior shell=2mm

- 100% TIG welding with pure argon gas shield

- Interior finish: external polished, 80mm insulation

- Manway: side manway or top manway

- 60~70 conical bottom for Fermener

- Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

- BBT carbonation stone

- Adjustable tank leveling pads

4. Cooling System

- Description: Chiller/Refrigerating + Glycol tank

- Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

5. CIP System

- Function: Use for cleaning tanks

- Component: Disinfection tank, Alkali tank (with heating element), Pump and so on. This components are significant part of beer brewing equipment.

- Purpose: It is used for heating, washing, cleaning all the tanks when it finish the brewing.

6. Control System

- PID control cabinet or PLC control with touch screen

- Mashing control, fermenting control, cooling control

Details:

Packaging:

1.20GP/40GP/40HQ

2.Packed with plastic air bubble film in fumigation free wooden case or fixed with iron frame

3.Up to export standard, suitable for delivery

4.Customer's requirements available

Certificate: