KEG WASHING FILLING LINE

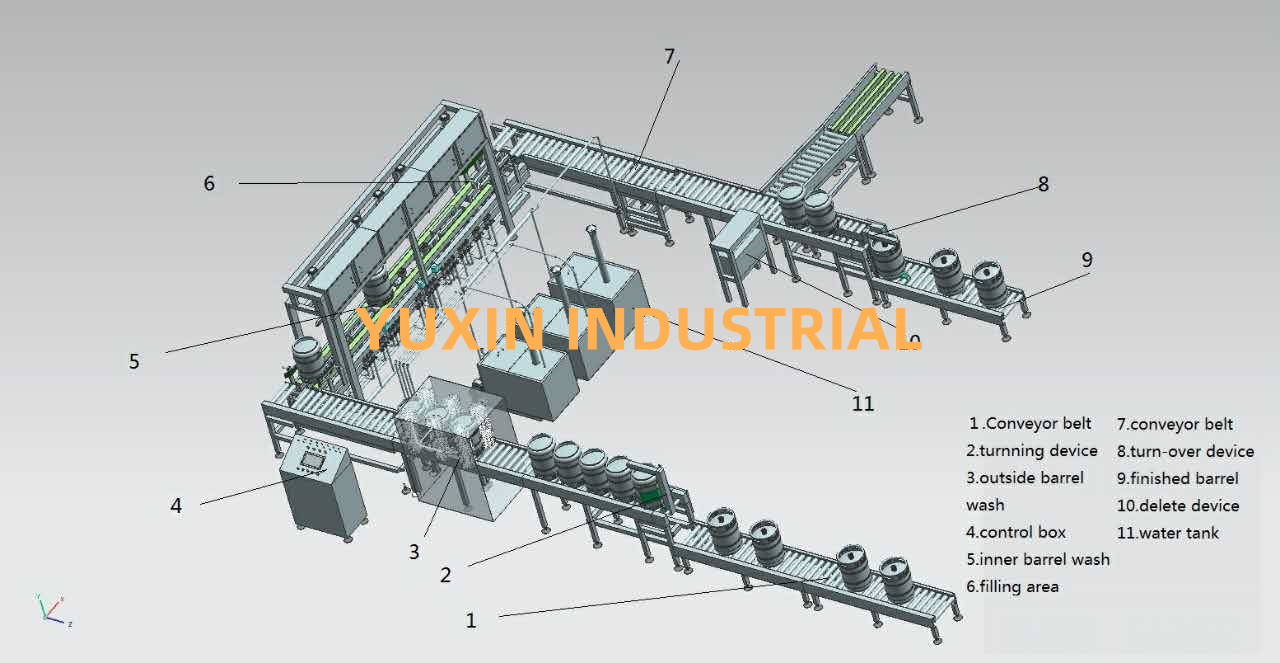

A full set of equipment includes cleaning, filling machine, control system, automatic weighing system, automatic conveyor system and related devices, etc.

KEG WASHING FILLING LINE

A full set of equipment includes cleaning, filling machine, control system, automatic weighing system, automatic conveyor system and related devices, etc.

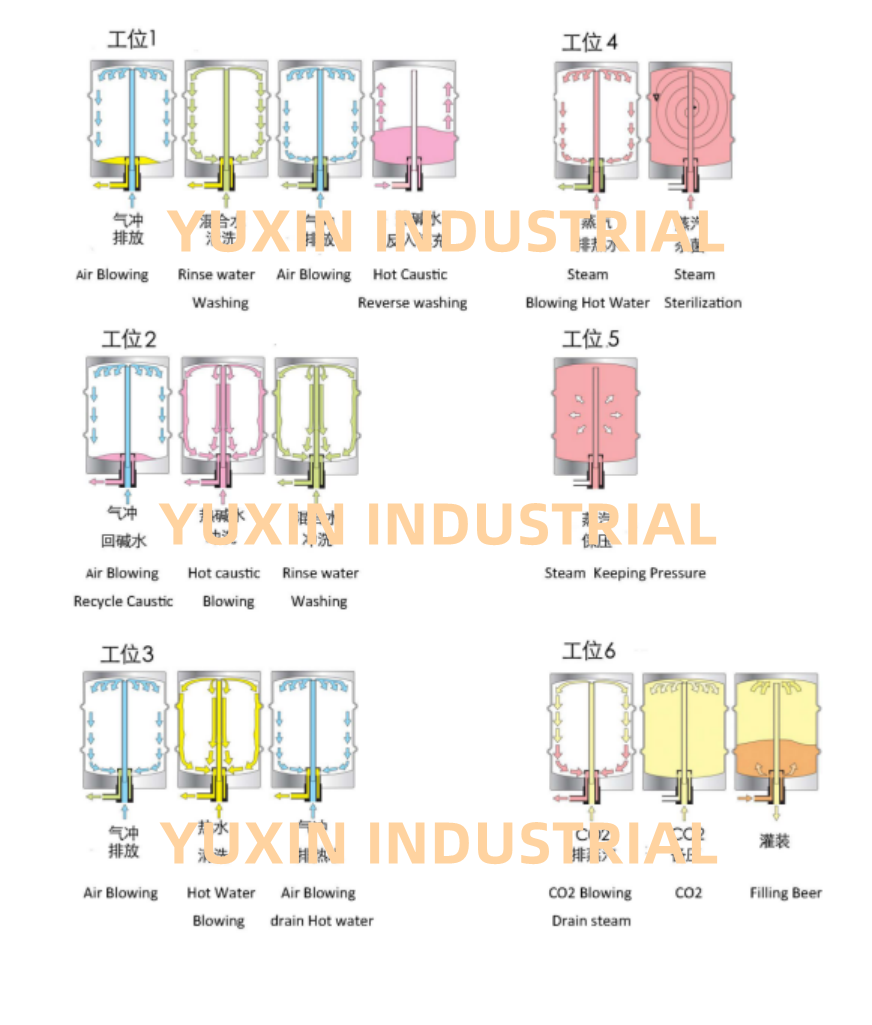

Work procedure:

(1) Put keg up-down on the conveyor, keg will prepare working automatically.

(2) Keg will prepare working automatically move to station 1 begin washing.

(3) Keg will move to station 2 washing automatically, at the same time, next keg will move on station 1 to prepare washing.

(4) Keg will finished wash, sterilize and fill from station 1 to station 6 as the same way.

(5) Keg will move on the weighing system to check up to standard or not by the conveyor.

1. Main part of Washing and filling line:

(1) This machine is a special cleaning and filling equipment for beer kegs, kegs can be 20/30/50L...., and spear can be A/S/D/G/M....

(2) The machine adopts fully automatic working mode, automatic completion of each station transfer and the cleaning and filling of each station, and no manual operation is required.

(3) There is a separate cleaning function, only cleaning and not filling, which can be used by pre-wash machine.

(4) Supporting manual operation and alarm display function for easy maintenance and maintenance of equipment.

(5) Real-time display of current work status and work procedures.

(6) The bucket of barrels is applicable to different capacity and standard range. It can adapt to the keg height 300-500mm; keg diameter 300-450mm; The upper end distance of the barrel extension is less than 22 mm.

(7) Mechanical driving mechanism adopts the linkage mode of mechanical crank, so that the equipment can run smoothly, reliably and accurately, so as to avoid the occurrence of failure rate.

(8) Device is equipped with automatic pressure detection, residual liquid detection after purging, wine spear open detection, sterilization temperature detection, alarm and location, the location after the alarm, the following location are to stop work and stop filling, can guarantee the physical and chemical indicators qualified filling wine, avoid the waste of alcohol.

(9) The filling is filled with CO2 backup pressure, and the pressure differential is sealed and filled. The filling volume is tested by imported flow meter, and different filling capacity can be set according to different capacity barrels. It can be used to ensure the low foam, low consumption, accurate filling quantity, and the alcohol loss can be controlled below 1%.

(10) The equipment has its own CIP and wine pipeline CIP cleaning function, which can guarantee the hygiene of the wine pipeline and the filling head, so that the wine can meet the hygienic standard. The wine after filling keeps the original taste and taste of beer.

(11) The filling method of the equipment can be set and adjusted by the touch screen to adjust the filling capacity, and can adjust the error, which can display the number of filling barrels and liters in real time. Normal filling error can be controlled at 0.2 L.

(12) The equipment is randomly matched with CO2 filter, steam filter and pressure-reducing valve to guarantee the expiration date of the finished product.

2. CIP system for keg inner surface

(1)The system has three/four CIP tanks and three/four CIP pumps, water tanks are Caustic, hot water and rinse water, sometimes also acid tank. The maximum lift of each pump is 40-45 meters. The automatic constant pressure valve is provided to washing and filling line.

(2) Caustic tank and hot water tank have automatic filling water, automatic heating and keeping temperature function to ensure the process requirements of CIP liquid.

3. Weighing system

(1) Weighing system is in a plate type electronic scale above supporting chain conveyor system, go through the chain transmission to run to the electronic weighing barrel according to the above, go through the chain suspension after complete automatic weighing process.

(2) Whether the bucket meets the weight standard is to use the actual weighing value of the bucket and the set value of the weighing instrument to compare the judgment; The actual weighing value is considered qualified if the value is greater than or equal to the set value.

(3) The maximum weight range is 150KGS.

(4) Whether the bucket qualified after weighing is determined by the control system and memory, when the unqualified bucket is delivered to the launch device, the device automatically pushes the bucket to the unqualified area; The qualified drums are not moved, and are transported directly to the finished area through the conveyor chain.

4. Conveyor chain:

(1) All inlet and outlet the conveyor chain adopt stainless steel chain roller chain, form a complete set of inlet and outlet blocking device, according to three lines of start-stop condition and counting mechanism at the same time supply three line into the keg and the keg of the output.

(2) The auxiliary photoelectric switch and the keg can be used to adjust the photoelectric switch according to the diameter of the keg, so that the keg can operate in the middle of the conveyor, so that it can be suitable for different kegs.

KEG WASHING FILLING LINE normally works together with flash pasteurizer system, and some clients will add a palletizing robot for final operation.

Now leave us a message or email us, to get a free quote!

Quick contact: +86-13355417900(WhatsApp & Wechat)