10HL Beer Fermentation Equipment

- YUXIN

- China

- 30-40 days

- 300 sets per year

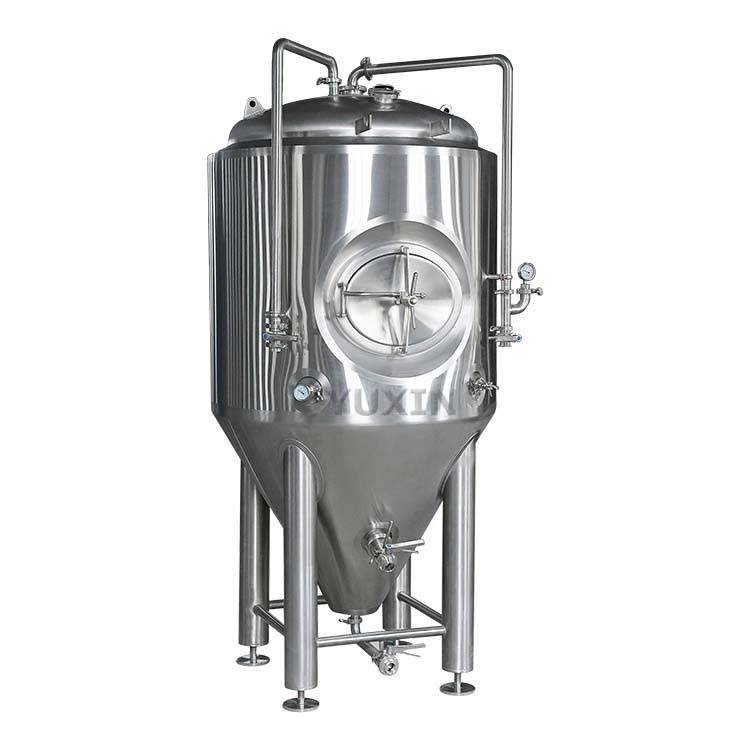

Our fermenters/fermentation equipment are designed specifically to meet unique and diverse brewing requirements. Whether small or large volume, customizable tanks are also available: single wall, un-jacketed and jacketed.

10HL Beer Fermentation Equipment

Fermentation Tank | With 25% head space; Inner(SUS 304) thickness: 3mm; Outer(SUS 304) thickness: 2mm; Insulation: Polyurethane, thickness=80mm; Single tank single control; Stainless steel cooling jacket on cone and side; Dish top, 60-75 degree cone bottom; Stainless steel manway( top or side); |

Accessories | Pressure valve, relief valve,Sample valve CO2 relief valve Glycol inlet and outlet Top Dry Hopping Port With spray ball for CIP cleaning Wort inlet and yeast outlet Racking arm Temperature and pressure gauges |

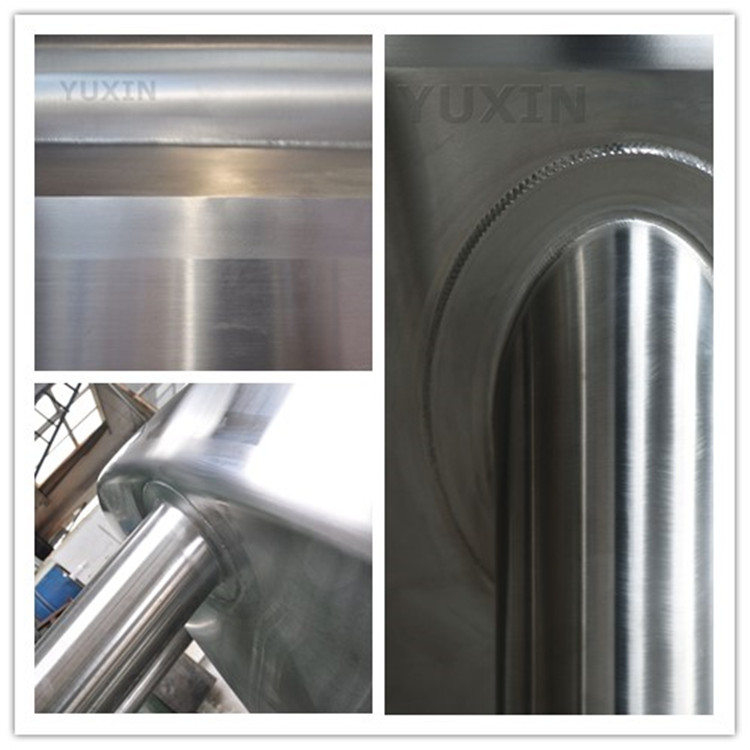

Details:

Polishing: Our polishing system consists of auto and semi-auto polishing machine and manual polishing. Each tank is polished three times and more polish for the key place.

Welding: Our argon central system for welding provides 100% pure argon to protect tanks from

distorting during welding.