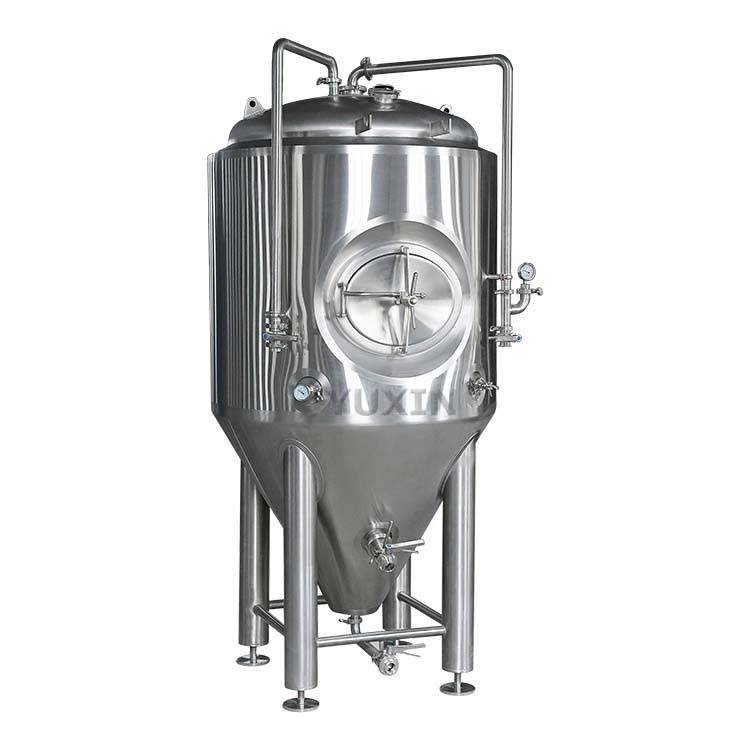

20BBL Beer Fermenter

- YUXIN

- China

- 30-40 days

- 300 sets per year

YUXIN 20bbl beer fermentation tank with:

dimple cooling jacket

with double walls and insulation

safety valve on the top

dry hopping port on the top

sample valve

racking arm

pressure valve and gauge

Two L-pipes

supply drawings, layout and loading diagram

customized as your actual space and electricity

engineer will go on site for installation/debugging and training

20BBL Beer Fermenter

Our fermenters/unitanks and brite tanks(maturation) are designed specifically to meet unique and diverse brewing requirements. Whether small or large volume, customizable tanks are also available: single wall, un-jacketed and jacketed.

Fermenter | SUS304 | 100L/200L |

Interior | SUS304 | Thickness 2.5mm |

Exterior | SUS304 | Thickness 1.5mm |

Bottom cone | 60-75 degree | |

Cooling method | Glycol cooling | Dimple jacket |

Temperature control | PT100 | |

Pressure display | Pressure gauge | |

Cleaning | SUS304 | CIP arm with 360 spary cleaning ball |

Insulation layer | Polyurethane | 70~80mm |

Manway | SUS304 | top or side manway |

Sampling valve | SUS 304 | Aseptic type, no dead corner |

Dry hops adding port | SUS304 | Optional, clamp type |

Carbonation device | SUS304 | Optional |

Yeast adding tank | SUS304 | 1L/2L |

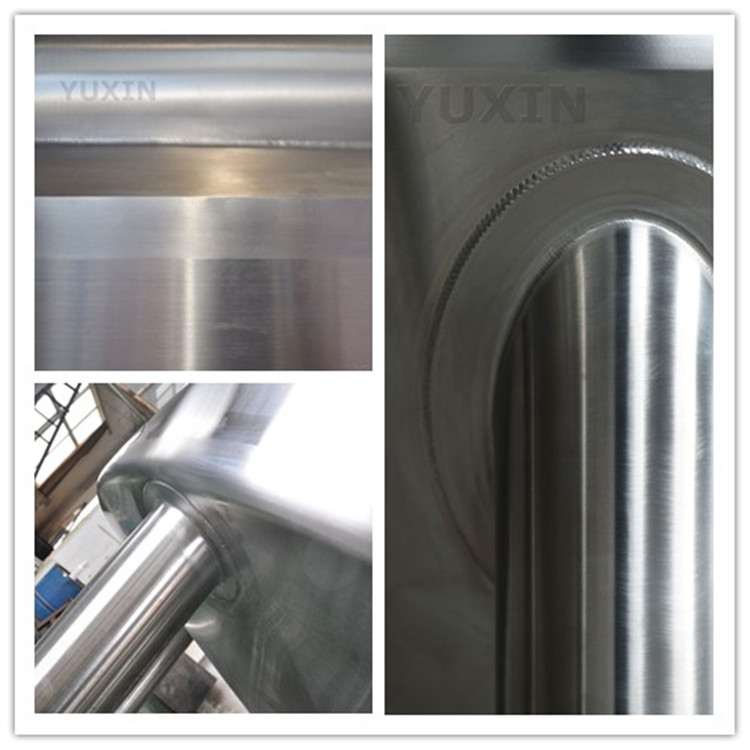

Detailed Images:

Polishing: Our polishing system consists of auto and semi-auto polishing machine and manual polishing. Each tank is polished three times and more polish for the key place.

Welding: Our argon central system for welding provides 100% pure argon to protect tanks from

distorting during welding.